Case Study: NIMBUS® Delivers Cooling For

Case Study: NIMBUS® Delivers Cooling For

Restaurant at The Ohio State University

VIRGA III® adiabatic cooling essential in satisfying the AHSRAE 90.1 standard economizer cycle requirement.

When students returned to The Ohio State University in the fall of 2018, a new fast food option was waiting to serve them in the heart of campus. Located on the ground floor of a six-story apartment building, the new restaurant's cooling includes a VIRGA III® hybrid adiabatic cooling system by NIMBUS®.

Initial plans for the restaurant specified a modular heat pump/chiller with cooling tower. Budgetary restrictions, however, called for a change in plans and the project contractor, G Mechanical Inc., partnered with Environmental Comfort (an Ohio-based supplier of custom HVAC solutions) to identify a cooling solution that would satisfy the economizer cycle requirement outlined in the latest ASHRAE 90.1 standard.

The typical design of direct expansion air conditioning (DX) rooftop units or split air handling units (AHU) were considered, but would be unable to satisfy the economizer cycle requirement due to a tight air shaft preventing the complete transfer of supply and exhaust during economization.

Ultimately, Environmental Comfort and G Mechanical Inc. paired a 60-ton air-cooled chiller in series with a two-fan VIRGA III (VRGA012) hybrid adiabatic cooling system for waterside economizer cooling. The chiller water is supplied to several smaller air handlers in the ceiling of the ground floor of the restaurant. The system also cools a small refrigeration unit for the walk-in cooler

The VIRGA III is installed in such a way that a diverting valve places it in series with the chiller. This approach enables the VIRGA III to minimize the demand on the chiller whenever outdoor ambient air temperatures allow (waterside economizer) -- reducing overall energy consumption.

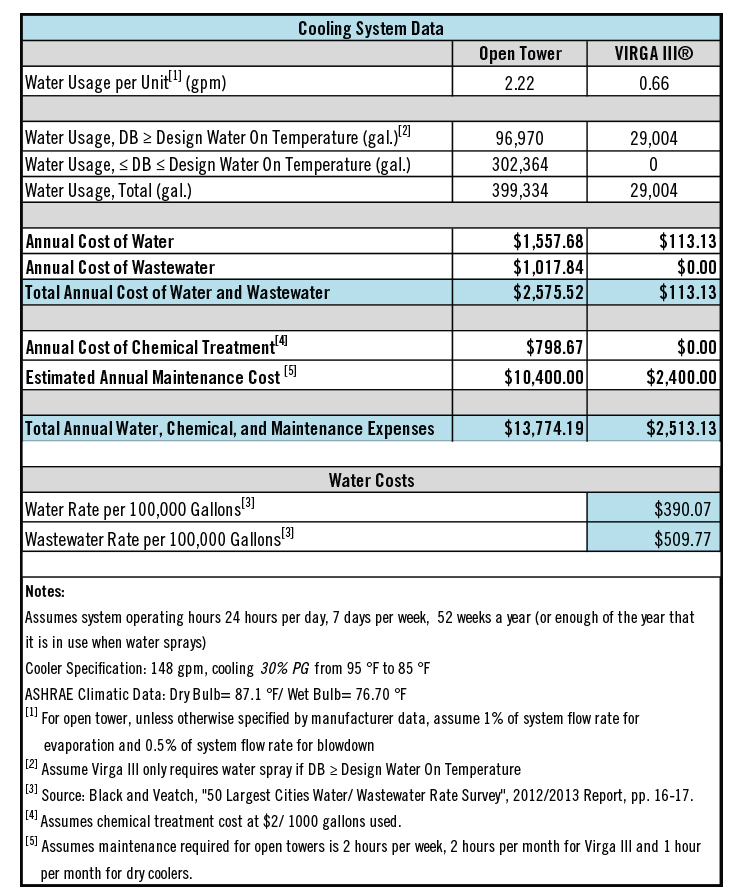

Additionally, the VIRGA III consumes less than one gallon per minute (0.66 GPM) when adiabatic spray is engaged. By contrast, a traditional open evaporative cooling tower sized for the same application would consume more than two gallons per minute. The chart below compares the water consumption of a traditional open cooling tower to that of a VIRGA III for this specific application.

By demanding significantly less water to meet the cooling requirements, the VIRGA III reduces annual water consumption by over 370,000 gallons and annual water costs by over $1,000. Since hybrid adiabatic technology does not produce wastewater, another $1,000+ is saved with the VIRGA III by eliminating wastewater disposal expenses. Once the nearly $800 annual savings in water treatment chemicals and the significant reduction in maintenance expenses (approximately $8,000) are factored in, the restaurant is saving $11,000+ annually by using a VIRGA III hybrid adiabatic cooling system by NIMBUS instead of a traditional open cooling tower.

There are two primary ways the hybrid adiabatic cooling technology used by VIRGA III and VIRGA X3™ reduces overall water consumption compared to traditional evaporative cooling towers. (1) Most of the year, VIRGA systems by NIMBUS operate as a dry cooling system, and only engage a fine water spray to augment the system's heat rejection capacity when outdoor ambient temperatures demand. (2) When the water spray is active, it consumes significantly less water (GPM) to achieve the desired outbound fluid temperatures compared to traditional evaporative cooling towers. The combination of these two factors allow VIRGA hybrid adiabatic systems to yield up to 95% annual water savings compared to traditional evaporative cooling towers.

If you have a unique cooling challenge, or are interested in conserving water, eliminating a primary breeding ground for Legionella bacteria, reducing energy consumption, and minimizing cooling system maintenance, then NIMBUS Advanced Process Cooling is ready to help you BE BLUE. Contact NIMBUS today at 844.NIMBUS.3 to begin custom-designing your cooling solution.