VIRGA Product Testing

NIMBUS® Advanced Process Cooling employs a team of cooling engineers, researchers, and developers from its state of the art in-house testing facility to ensure it delivers cutting edge hybrid adiabatic cooling systems. NIMBUS’ latest innovation, the VIRGA X3®, is the result of NIMBUS’ investment in its team and research capabilities.

VIRGA Hybrid Adiabatic Cooling System Performance Testing

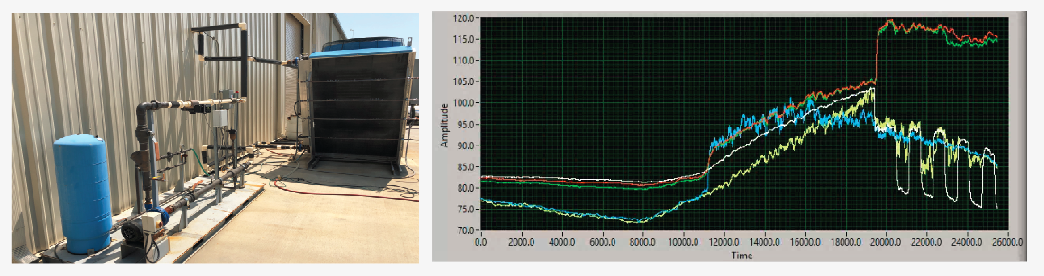

All VIRGA hybrid adiabatic cooling performance specifications are based on real experimental data. NIMBUS utilizes an in-house 25-ton fully-automated test facility where a dedicated VIRGA X3 unit (VRGA021) is stationed for adiabatic performance testing. Here, the NIMBUS R&D team carefully monitors the unit and puts various spray nozzles and spray configurations to the test throughout the months in which the adiabatic spray would be utilized. This enables the NIMBUS team to generate an adiabatic cooling performance map to identify different ranges of outdoor air temperature and humidity. Additionally, the NIMBUS test facility is capable of operating and collecting data 24/7. Measurement equipment, such as temperature sensors, is carefully monitored and calibrated by the NIMBUS engineering team. Multiple temperature sensors are employed at each measurement point for the ensured accuracy and repeatability of results.

Water Hardness Testing

Water Hardness Testing

NIMBUS R&D also conducts in-house water hardness testing. Water hardness varies for each installation location (generally from 50ppm to +600ppm), and plays an important role in informing the unique installation and maintenance requirements of any cooling equipment that uses water. At NIMBUS’ fully-automated and supervised test facility, a team uses a VIRGA III® system (VRGA001) to study the impact different water hardness levels have on the cooling system with and without the use of a water softener. Tests are planned for hardness level ranges from 100ppm to 700ppm, and the impact of each water hardness level on the spray system and coil surface is recorded and evaluated. Additionally, NIMBUS tests and evaluates different chemical and non-chemical water softeners to recommend the ideal water softener to keep your VIRGA III or VIRGA X3 hybrid adiabatic cooling system at peak operational performance.

Nozzle Life Cycle Testing

Nozzle Life Cycle Testing

Spray nozzles are a key component of the the adiabatic cooling process, and it is critical for the NIMBUS team to acquire a thorough comprehension of the behavior and life expectancy of the nozzles used on VIRGA hybrid adiabatic coolers to minimize clogging in hard water environments. The NIMBUS R&D team independently collects this data by conducting in-house nozzle tests 24/7 for +10,000 cycles per nozzle type at different water hardness levels (100 - 700ppm). The results are recorded using a fully automated data collection system and then evaluated—ultimately informing NIMBUS’ team of engineers on which nozzles are best for each application.

VIRGA Life Cycle Testing

NIMBUS is dedicated to delivering cooling solutions that are dependable, durable, and able to deliver years of effective, economical cooling. To ensure NIMBUS’ promises of system longevity are delivered upon, and that every minor nuance and potential concern is observed, a VIRGA III (VRGA017) system has been employed as part of the cooling system at NIMBUS’ own Anniston, Alabama manufacturing plant since 2016. NIMBUS not only relies on this particular VIRGA system for its own cooling in the brutal Alabama heat, but NIMBUS’ R&D team monitors and observes this system constantly. Additionally, to simulate and collect data on “worst-case scenario” operating conditions, NIMBUS performs zero scheduled maintenance on the installed unit to gain an understanding of how a neglected system will behave as it ages. Since its installation in 2016, this particular VIRGA system has operated flawlessly with zero down time and no major issues. While this is not an endorsement of a “zero maintenance” plan—NIMBUS does NOT condone neglecting your cooling system and reminds you it is an investment and to get the most out of your investment you should always follow-through on recommended scheduled maintenance of your system—it is a testament to the durability of NIMBUS’ VIRGA III and VIRGA X3 hybrid adiabatic cooling system design.

For more information about VIRGA III, VIRGA X3, or hybrid adiabatic cooling, call NIMBUS today at 844.NIMBUS.3!